Following Puerto Rico, I was offered a gig building lasers for a company in Baltimore. I had been out of work for a few months and needed the money so I took on several weeks to build 30 lasers for Paul McCartney’s world tour. It would test my time management skills, but the practice in soldering and crimping would save my butt in the end.

The next few months was a balancing act. Every hour not working on lasers was money lost, but an hour less to work on the couch. We had a few things to figure out and build beyond the upgraded brakes and wheels. A coffee table, side pods covering the wheels, back and front panels and chandeliers.

Luckily we had some collaborators all doing their part. Adam had the music pretty much by January so we had music to listen to while working.

Charlotte was working on the creature outfit. She had the ghillie suit but wasn’t sure where to go next. We wanted to hang out anyway so we headed out on an expedition to find inspiration around the harbor itself. This helped her get a idea of the way the trash and weeds and bay become intertwined.

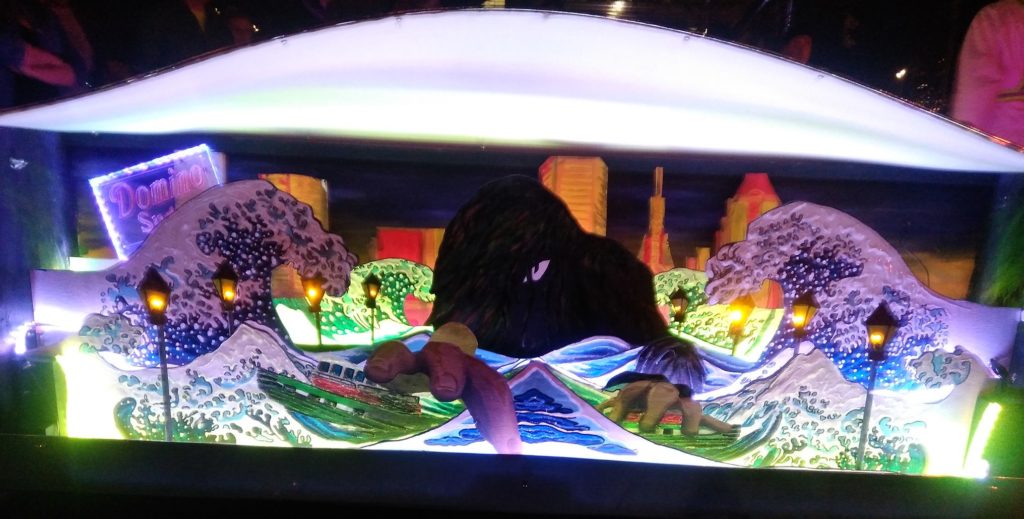

And Katlyn worked on the mural for the back first drawing up a everything on the computer in order set up the layers and then being able to project it on to the wall. The end result is pretty incredible and a piece of hangable art all by itself.

Katlyn’s amazing mural showing The Wave, a painting from Baltimore’s sister city Kawasaki Japan as it crashes over the Fells Point Pier

First I found time to build up the side pods. We used thin plywood panels reinforced with bulkheads and mostly wood glued together. This we covered with chrome vinyl.

It’s pretty amazing how close this turned out to the renderings considering I was just winging it the whole time.

From there we played around with our materials and found a cool way to put LED strips behind chrome covered acrylic. When the lights were off it was just chrome, but when they were on the would since right through.

<iframe width=”854″ height=”480″ src=”https://www.youtube.com/embed/HR0nLiYf1GY” frameborder=”0″ allow=”autoplay; encrypted-media” allowfullscreen></iframe>

For the table we decided we wanted it to look thick, but not weigh or cost a ton so we drew it up on Sketchup to get the most out of a single 4×8 sheet of 3/8″ acrylic. We doubled up the perimeter to 3/4″ by welding them together and added 4″ underneath to make it more rigid. We sort of got it right, but with a ton of mini bubbles trapped inside. Whatever! Cleaned up the sides and lit it with a strip in the center. It was amazing at night. The acrylic carries the light from the led’s through to the edge where it GLOWS.

Once the table was done we needed to put some things on it. A global positioning system and some disco snacks.

I had to wire up each piece of fruit. 4 male, 4 female pins on each. Something like 80 pins to crimp total. Can plug it into a regular 12v power brick though and is controlled by a remote so we can use it anywhere in the house.

In the end we built a pretty sweet couch

Beyond the physical couch was the hours of work provided by our performance artists / spotters. For six hours each night, our team of dedicated workers would suit up and escort the couch around little piece of the festival.