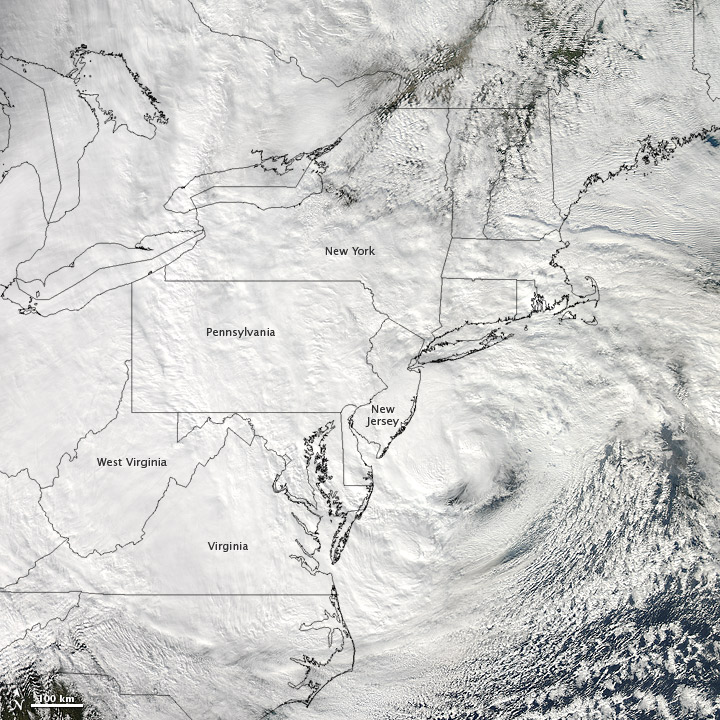

Rain was already starting to fall as we patched the last of the holes in the roof Sunday afternoon. The day before, dad helped us to add the missing flashing (where we had removed the chimney), tar suspected leaks, and install the 3rd floor window. All of this needed to get done, but we didn’t think we’d be doing it in preparation for a massive tropical storm. The massive storm was Sandy and it was due to make landfall only 100 miles east of us on Monday.

Having done what we could to prepare, we spent the rest of the weekend with dad, who helped us to install aluminum heat reflector paper and insulation above the bathroom, finish up the bathroom vent and wiring, get the bathroom ceiling drywall up, and plane the 1″ floor boards down to match the missing floor board on the 3rd floor. Around 9 I got a text saying work was closed Monday so at least I could be around to keep an eye on things.

When I arrived Monday, we already had an inch or two of water in the basement. We don’t have a sump pump so we used the shop vac to bail out the water. After taking a few bucket loads up the stairs, I decided it was time to finally hook up the drain on the utility tub. Throughout the day we needed to vacuum up about 30 gallons of water every hour or so.

Between vacuuming we were able to get a wall of drywall up in the bathroom. Siri worked on the thin-set and backer board on the other half of the room. With no insulation on the roof, the sounds of blowing wind, banging flashing and hard rain seemed even worse.

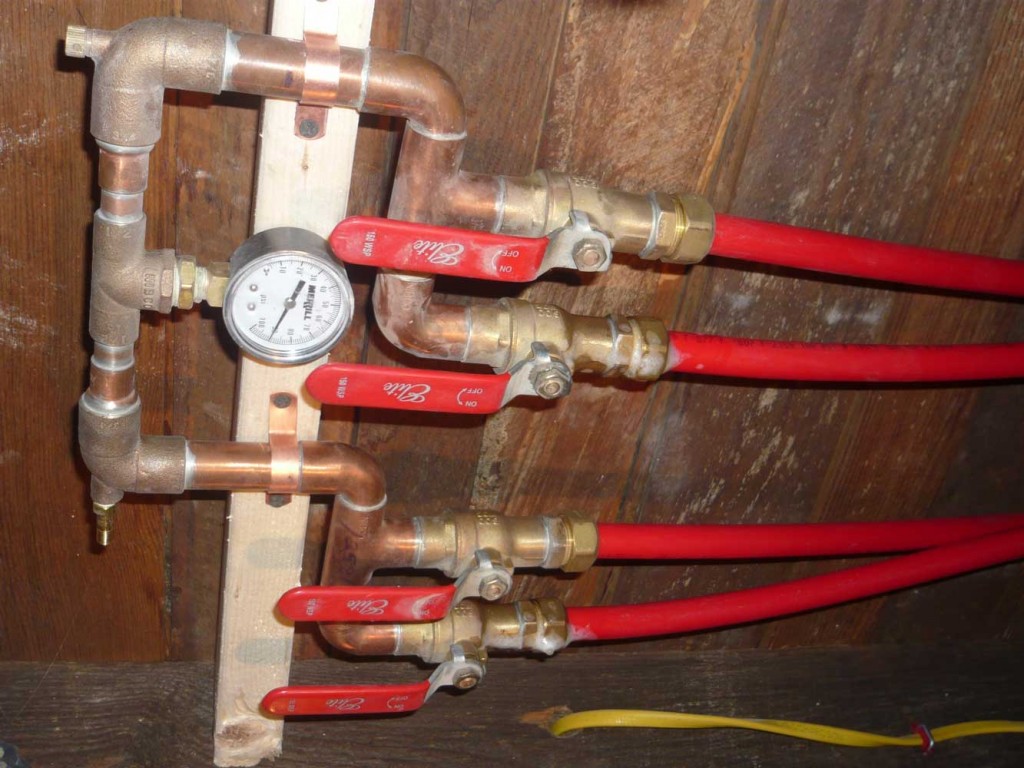

Tuesday morning we were pretty nervous coming to the house. The news had said that the worst winds would be in the middle of the night. Luckily the tree had not blown down, we still had power and the basement was dry; winds had changed direction in the night and stopped forcing water in the back of the house. I was able to finish up the drywall in the bathroom, cut the floorboards to size, do a little wiring, and help Siri get more backerboard up. We got really lucky when we cut a section of floorboards out. I had set the depth on the saw and cut the boards and then Siri reminded me that there was PEX under that board. Upon inspection we had missed the pex by maybe a millimeter. Close call!

In the end we were lucky all weekend. We had power the whole time, no downed limbs, no excessive flooding, no massive leaks; Hurricane Sandy gave me two paid days off work and we used those every hour of them.